Ammeter, panel wiring and gauges

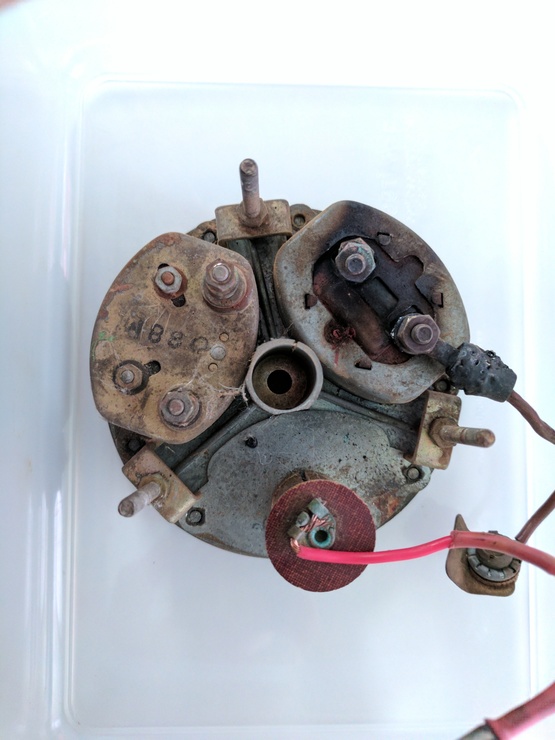

Prior to installing the new wiring harness, I checked out the condition of what was behind the instrument panel. I’m glad I did, since while I knew the test sockets needed replacing, I also noticed the ammeter was quite damaged from the heat around it - or maybe it too had shorted? In any case, it didn’t work, so I removed it, and I’ve ordered a new one.

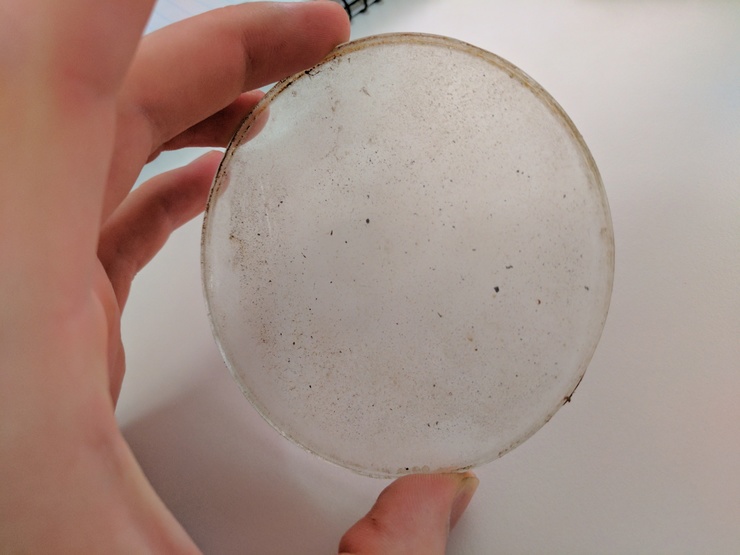

When I removed the ammeter, probably the first thing I noticed was the condition of the rest of the instrument panel - it was full of dust, so I decided to clean it out, as well as the individual gauges. I forgot to take a “before” shot of the panel and gauges, but you can probably guess how bad it was from the before shot of the glass:

And after (before and after refitting the gauges). It doesn’t look 100% clean since the outer face is covered in small nicks and scratches, as expected after 50 years, and some of the black paint on the face/gauges has worn off. The scratches are much less visible in real life.

The bezel is still in pretty rough shape, but I don’t have room for a painting rig (or paint storage, or an air compressor…) so it’ll have to wait. I also need to figure out what to do with the badly-perished rubber seals, I’m looking at Sugru as an option since the seals aren’t listed in the parts manual, and I can’t find them available anywhere (unless I buy a replacement instrument cluster, which is $300 I don’t need to spend).